The dominant process for modern steelmaking is based on the Basic Oxygen Process where carbon rich molten iron has high-purity (>99.5%) oxygen blown through it to remove impurities and produce low-carbon steel. Carbon is removed from iron via oxidation and comes out mainly in the form of carbon dioxide and carbon monoxide.

Most steel manufacturing utilizes blast furnaces, and analyzing the gas that comes out of a blast furnace is challenging due to the high temperatures and particulate content until it is cooled, treated, and sent to furnaces to pre-heat the blast air. Oxygen measurement can be done on the blast gas to ensure purity, and on the flue gases that are vented from the furnaces to check if the air/fuel mixture is optimal for efficient combustion.

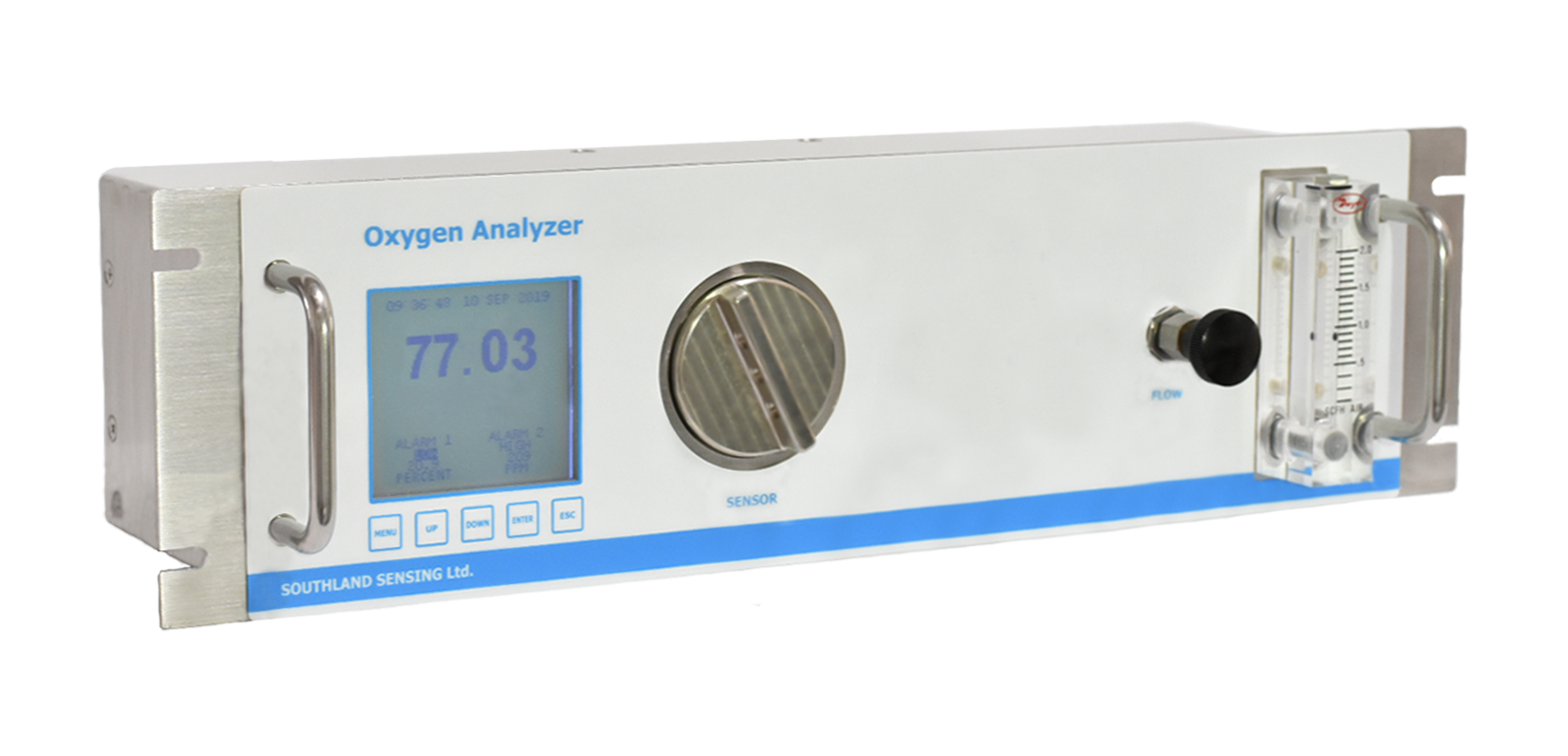

The OMD-775 inline purity analyzer can be used to ensure adequate purity levels in blast gas, and the OMD-740 provides the same technology in a portable package for spot-checking. For measuring oxygen content in the flue gas, the OMD-150 is packaged in a rugged IP66 enclosure suitable for outdoor installations and can easily measure the percent level oxygen concentrations that are present.