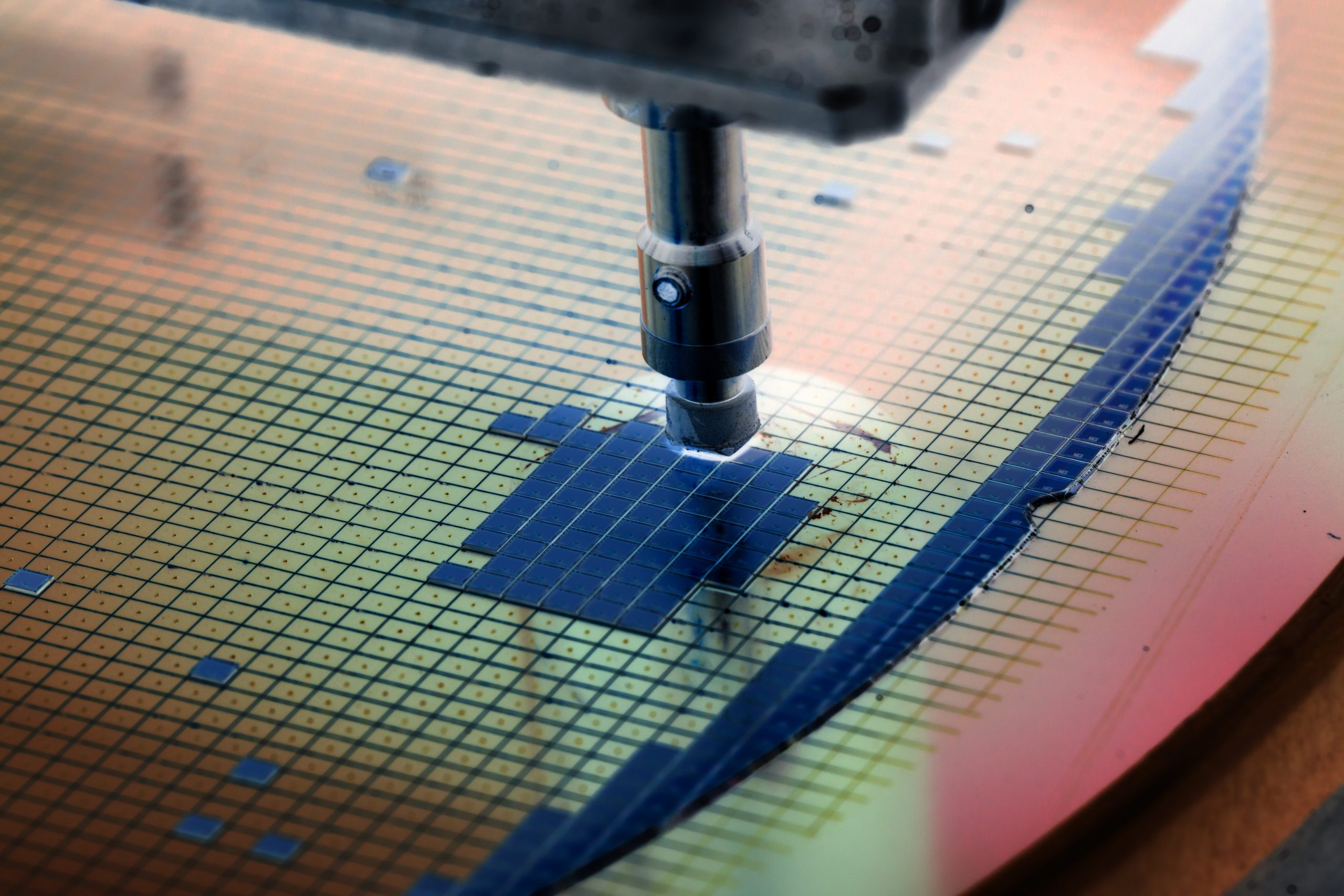

At the core of most electronic devices are semiconductors – materials with electrical conducting somewhere between conductors and insulators, most commonly silicon. As microprocessors continue to get smaller and the quality standards increase, semiconductor manufacturing techniques have become more precise and demand more sophisticated tools. The patterns etched onto chips are extremely complex and dense, and chips can have around 4km etched per square centimeter.

Nearly all processes take place in inert atmospheres inside of metal walled reactors or chambers to avoid contamination – even oxygen in the parts-per-billion levels can cause loss of yield due to unwanted reactions with the chemicals involved.

Since the tolerances for gas levels are so low, extremely sensitive gas analyzer technology must be used. Our precision electrochemical sensors are able to measure oxygen in the 0-1 PPM range, with a resolution of 0.001 ppm, or 1 ppb. The OMD-675 and OMD-677 provide this level of precision in a 19” rack or panel mount configuration for continuous monitoring of your gas, and the OMD-640 utilizes the same technology in a portable package for spot-checking gas purity.