In manufacturing and research there are many materials and processes that are sensitive to air, moisture, and dust, and require a controlled environment. The simplest way to handle these materials is inside of a glovebox, or containment chamber, that has an atmosphere consisting of only an inert gas such as nitrogen or argon. Inert gloveboxes that can maintain low oxygen and humidity levels for a long time are critical, as leaks can compromise the integrity of the contents within.

To achieve an inert environment, the simplest method is to evacuate all the air inside of a chamber and re-fill it with an inert gas. To reduce the amount of inert gas required, some gloveboxes also run the gas over a catalyst bed that continuously removes oxygen and moisture.

Oxygen sensing is critical for these gloveboxes to confirm that the environment is inert and your glovebox does not have a breach, and an electrochemical sensor is considered one of the most robust sensors for this type of application.

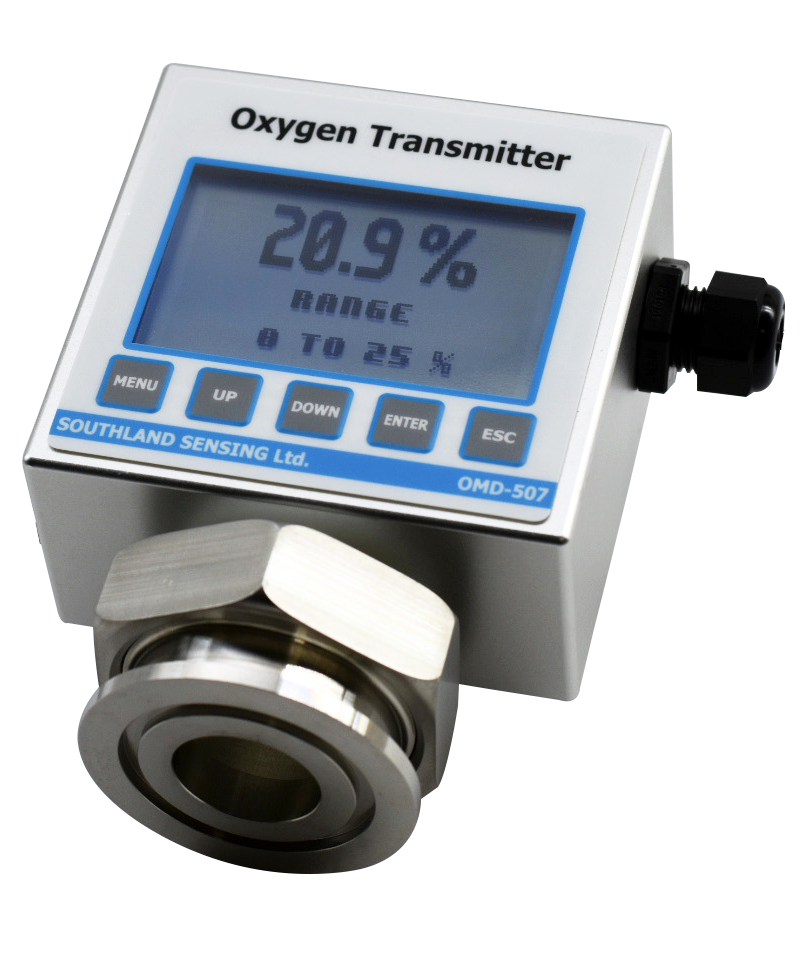

We manufacture oxygen analyzers purpose-built to be used with inert gloveboxes, including our OMD-501X panel-mount oxygen analyzer and OMD-507 online oxygen analyzer. These can measure oxygen from .01 PPM up to 25.0% using our state-of-the-art electrochemical sensors and are offered with a convenient KF40 (NW40F) flange for direct mounting to your glovebox, as well as an inline flow through configuration.