Many industries, including the automotive and aerospace industries, are increasingly using reactive metals such as titanium due their durability, low density, and high corrosion resistance. Due to the expense of these materials welding procedures need to be carefully developed to avoid waste, rework, or risk of failure.

Reactive metals are very prone to oxidation at the temperatures required to weld them, which can result in discoloration and affect the mechanical properties. Oxygen contamination can increase tensile strength, but it comes at the cost of ductility and corrosion resistance. Protection from oxidation is often done with blanketing the material with an inert gas prior to the weld to minimize oxygen levels. This is often done by sealing the inside of a pipe and displacing all air with a laminar flow of an inert gas such as argon.

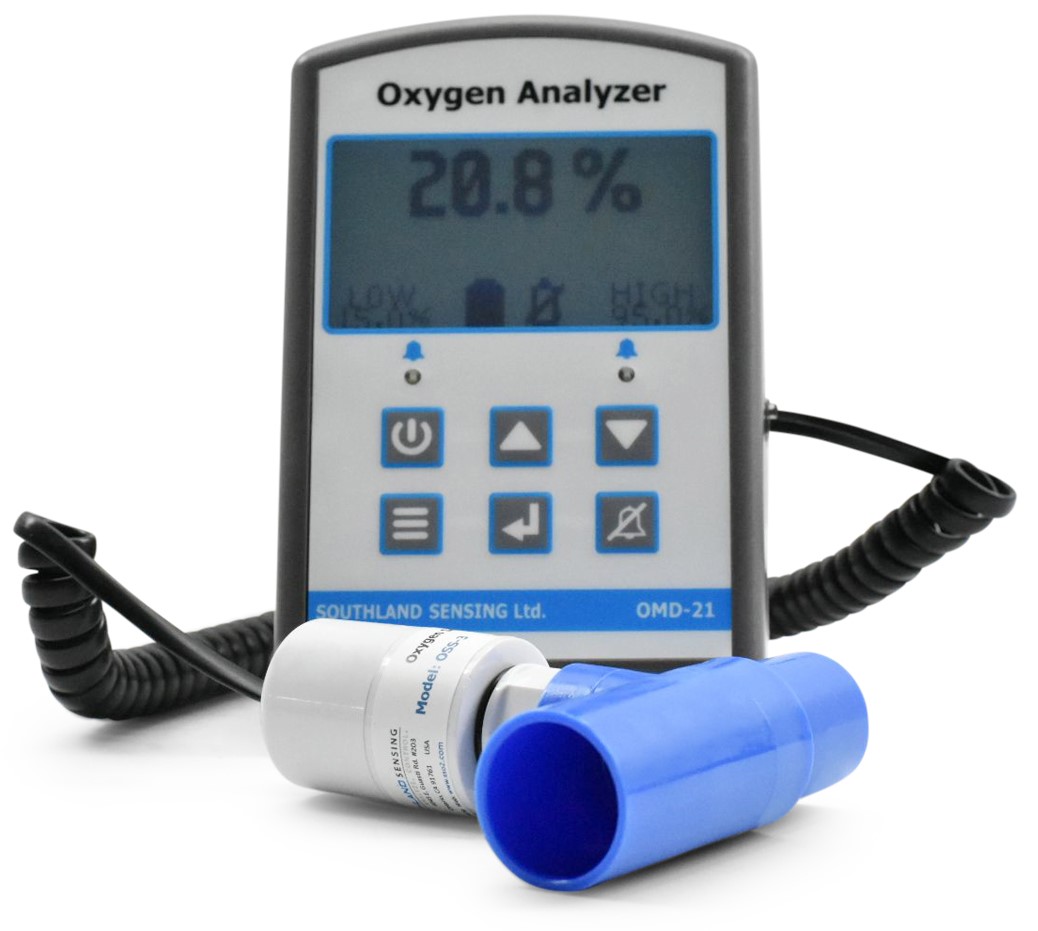

Typically, applications that require shielding gas need an oxygen level lower than 20 ppm. We manufacture analyzers that can be used to measure oxygen levels both portably and online, for welding in gloveboxes/welding chambers or in portable purge chambers in the form of our OMD-507 and OMD-580 respectively. Both are capable of measuring down to 10 ppm, and the OMD-507 is offered with a convenient direct-fit KF-40 fitting to fit directly onto an open KF-40 port in a glovebox to ensure the atmosphere in your chamber is inert.